Blog Sweven

Cloud computing is now the standard, no matter in which industry you are. It has proven to be safer, cheaper and, unarguably, …

Categories

Speed – Confidence

See how we work in your industry to provide speed and confidence in our most common industries. When transitioning from scratch to start a business

Work Smarter

Today’s industries are looking for new and smarter ways to improve quality and productivity with no major change preferably. As a part of covering all

Backlog Management

Control of backlog is fundamental to successful management of the maintenance function and thereby to realization of reliability. It must be held within manageable control

Avoid Unexpected costs = Improved Performance

Preventive maintenance will keep your systems in top condition and avoid future cost repair work. ECOBPM understands and prioritizes the importance to keep up with

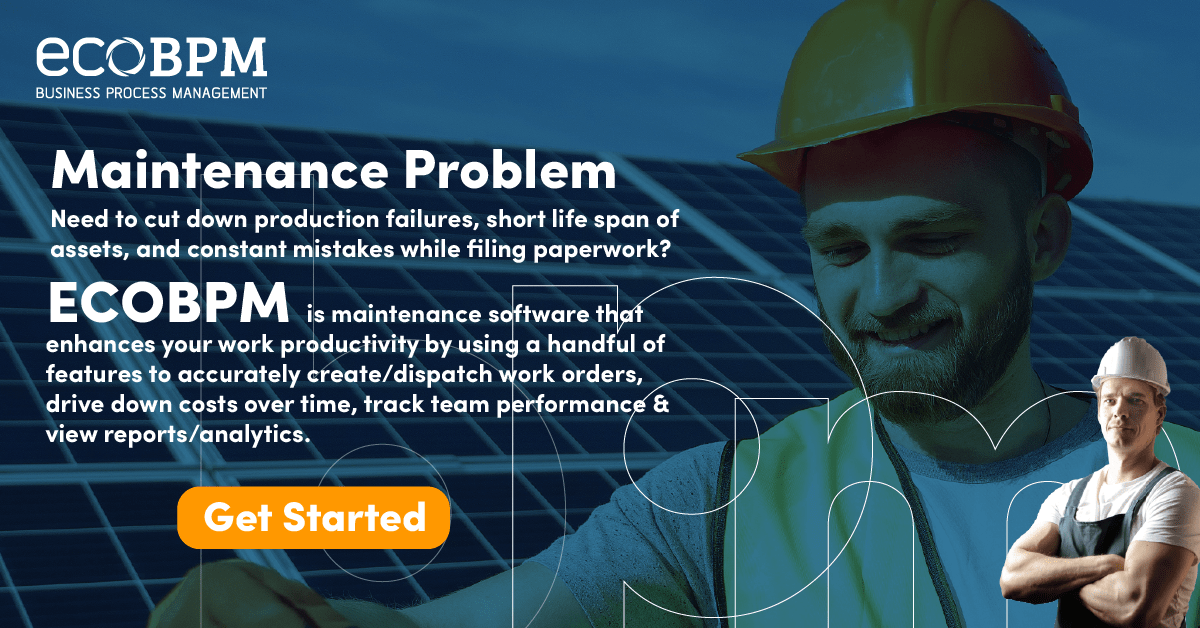

Computerized Maintenance Management System

A computerized maintenance management system (CMMS) is a type of management software that performs functions in support of management and tracking of Operation and Maintenance

Frustration with Planning

Disenchantment in implementing a planning organization is frequently due to an attempt to provide detailed work plans on reactive jobs. Since reactive jobs by their

Reactive Maintenance. If it works, don’t fix it

Reactive maintenance is done when equipment needs it. Inspection with human senses or instrumentation is necessary, with thresholds established to indicate when potential problems start.

Command, Control, and Communications

• Reliable and accurate communication is critical to the organization’s emergency plan.• Facility Managers must understand there is internal and external communication. They must do

The Nature of Maintenance Activities and Related Organizational Structure

Most maintenance departments are organized only for reaction to urgent demands, yet they wonder why they live in a reactive environment with a reactive culture.Organizationally,

Focus on Future Work

The Planning Department concentrates on future work—work that has not been started—in order to provide the Maintenance Department at least one week of work backlog

Why Improvement Is Needed in Maintenance

Effective maintenance reduces overall company cost because production capacity is available when needed. The company makes a product with this capacity to sell at a

Where Planning Fits Into Good Maintenance Practices

When a maintenance planning and scheduling function is being established, the first questions that usually arise are where and how it fits into the organization.